GACs Technology

GACS (Geochemical Active Clay Sediment) is a process created, developed, and patented by ZEOLOGIC which:

Is friendly to the environment,

Can be applied to a wide range of environmental issues

Is based upon the usage of geopolymer materials with high absorption ability

Relies on the principles of nanomechanics, achieving treatment of the pollutant load at nanoscale level. Pollutant load is captured on the crystal structure of the geopolymer materials

Produces inert , stable and non-hazardous sludge

ZEOLOGIC has developed a series of innovative products such as, nanocoagulant mediums, nanoflocculants, organoflocculant compounds, and metallic oxidation nanoparticles, which together with the geopolymer materials significantly enhance the performance of the treatment process.

The Gacs method main advantage is the specialized approach in each type of waste, achieving the maximum pollution load absorption in every waste treatment line. The success of GACS Method relies on the foundations of nanomechanics, and the unique utilization of geopolymer materials per application after the simulation of each offered solution in our fully equipped Laboratory by the R & D department of the company.

ZEOLOGIC produces the required chemical consumables in its own facilities and supplies with them the waste treatment units it executes, ensuring that way the quality and availability necessary for their long-term operation.

Treatment

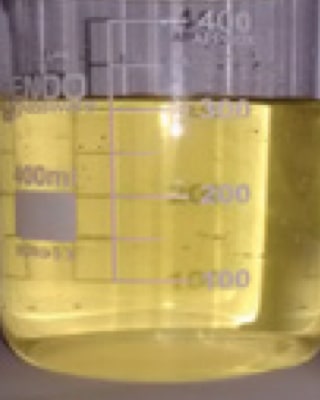

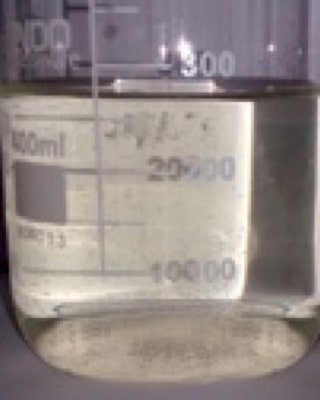

A typical waste treatment, applying the GACs method, as well as some typical procedures are presented below.

GACs Technology

Key Benefits

High degree of automation

Remote control of the plant

Customized approaching in every type of waste

No influence from climatic conditions to the treatment process

Significantly lower reaction times

Upgrade on existing waste treatment plants also possible

Competitive investment cost compared to other treatment methods

Significantly lower operational cost in use of chemical consumables

Lower energy consumption

Lower maintenance cost

High reuse ability of treated waste.

Significant pollutant load reduction

Production of inorganic sludge without toxic or dangerous characteristics

Small treatment plant footprint

Elimination of irritant odors

Lower volume of produced sludge

Read our News here

LEARN MORE